LHGC nwere ọgụgụ isi mmanụ-mmiri jụrụ vetikal mgbanaka High gradient magnetik separator

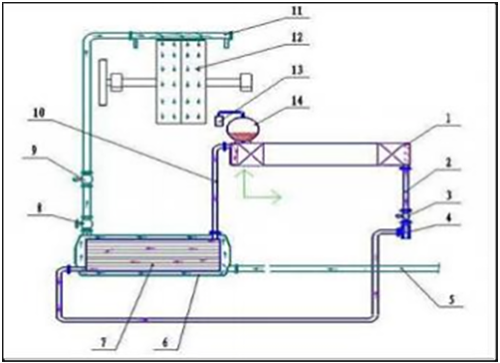

Nkọwapụta Ụlọ ọrụ

Shandong Huate Magnet Technology Co., Ltd, Onye na-eweta ọrụ Sistemụ Ngwa Igwe Ọdụdọ nke ụwa, tọrọ ntọala na 1993,

na isi ụlọ ọrụ na Weifang, China na mkpokọta 270,000 square mita na ihe karịrị 800 ọrụ. Huate Magnet bụ ọkachamara n'ichepụta magnetik superconducting, akụrụngwa nkewa magnetik cryogenic, mgbanaka kwụ ọtọ high gradient magnetik separator (WHIMS), slurry electromagnetic separator, magnetik iron separator, magnetik stirrer, ultra-mma egweri na nkewa akụrụngwa, Ngwuputa asọmpi set akụrụngwa, ọgwụ magnetik. resonance imaging (MRI) wdg. Ọrụ ọrụ gụnyere nke m, coal, ọkụ eletrik, ihe owuwu ụlọ, metallurgy, metal na-abụghị ígwè, nchekwa gburugburu ebe obibi, ahụike na ihe ndị ọzọ karịa ubi 10. N'ihe karịrị ndị ahịa 20,000, ebupụla ngwaahịa Huate na mba 30 dị ka Germany, Australia, Czech Republic, India, Brazil na South Africa.

Nka nka

1. Mmanụ-mmiri Okpomọkụ Exchange Technology

Igwe mmiri ahụ na-anabata nnukwu mgbasa nke mpụga mmanụ-mmiri okpomọkụ maka mwepu okpomọkụ. Ngosipụta okpomoku ikuku na-erughị 25 Celsius C, attenuation ikuku magnet dị obere, yana ndenye nhazi nke ịnweta kwụsiri ike. Igwe mmiri ahụ na-anakwere ihe owuwu mechiri emechi nke ọma, nke na-egbochi mmiri ozuzo, uzuzu na-eguzogide corrosion, nke nwere ike ime mgbanwe na gburugburu ebe ọrụ siri ike.

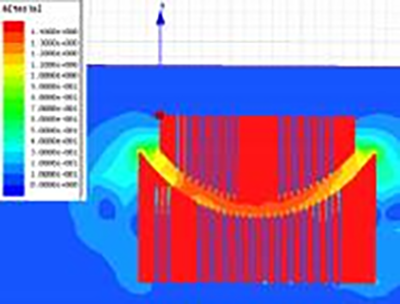

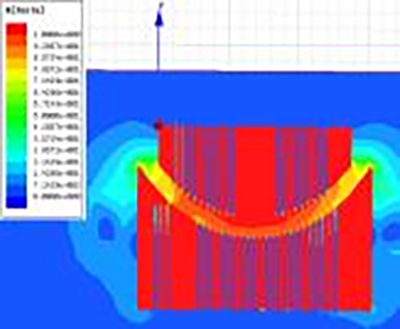

2. Kpọmkwem Igwe Ọdụdọ Igwe Ọdụdọ

N'iji njikarịcha ịme anwansị mmewere, imewe sekit magnetik bụ ihe ezi uche dị na ya, ọnwụ ike ndọta dị obere, na ike ndọta nwere ike iru 0.6T, 0.8T, 1.0T, 1.3T, 1.5T, 1.8T.

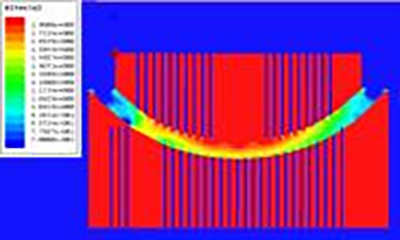

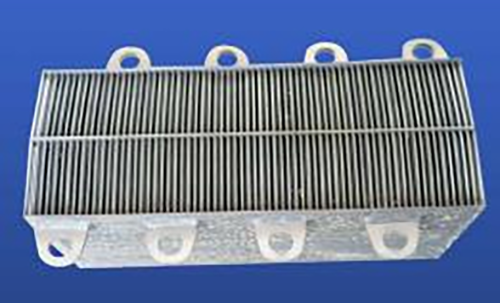

3. Magnetic Matrix Integrated ogologo ndụ

Matriks ahụ na-eji otu akụkụ site na ụdị ihe owuwu, na mkpanaka ndị na-ajụ ase adịghị adapụ; na-edozi efere akpa na-eji usoro nhazi conical, na ike njikọ dị elu; a na-eji ngwá ọrụ rọbọt pụrụ iche gbachie ya, nke nwere àgwà a pụrụ ịdabere na ya na mgbanwe siri ike.

4. Na-agbapụta Sistemụ Mwepụta Ngwunye Mmiri

A na-achọpụta nrụgide nke mmiri na-agbapụta n'oge dị adị, nke mere na mmiri na-ekpo ọkụ na-eme ka nrụgide zuru ezu na mmiri na-asọba, na mineral ndị dị na matriks ahụ na-ahapụ nke ọma.

5. Sistemụ njikwa akpaaka nke ọkwa Liquid

A na-achọpụta ọnọdụ mgbanwe nke mmiri mmiri nke ụlọ nkewa na ozugbo site na ultrasonic sensọ, ọ na-ejikọta ya na onye na-eme ihe ọkụ eletrik, nke mere na ọkwa mmiri mmiri nke ụlọ nkewa ahụ na-anọgide na-enwe mgbe niile na steeti nkewa kacha mma; arụ ọrụ ntuziaka na-ebelata, na-ebelata ihe isi ike nke nyocha akwụkwọ ntuziaka; A na-egbochi oke slurry ozugbo ka ọ ghara ịfefe oke.

6. Usoro mkpuchi mkpuchi okpomọkụ

A na-enye ihe mmetụta okpomọkụ nke eriri igwe iji chọpụta ọnọdụ okpomọkụ nke eriri igwe na-arụ ọrụ ozugbo wee weghachi ozi ahụ na etiti njikwa. Mgbe okpomoku mkpuchi ahụ gafere uru a tọhapụrụ, sistemụ ahụ ga-ama jijiji na-akpaghị aka, na akụrụngwa ga-akwụsị ịrụ ọrụ mgbe oke oke ruru iji hụ na arụmọrụ akụrụngwa dị mma.

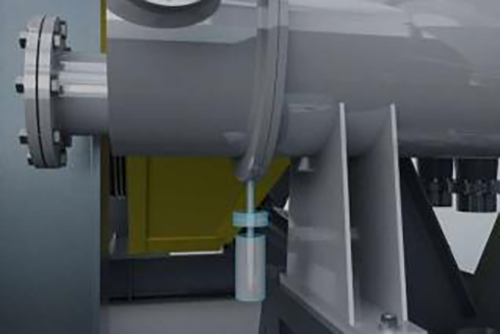

7. Ngwaọrụ mkpu na-agbapụta

Igwe nju oyi na-anakwere ihe owuwu tube-efere nwere okpukpu abụọ, ma enwere ngwaọrụ nchọpụta ntapu n'etiti ọkwa. Mgbe ntanye na-apụta, akụrụngwa ga-ama jijiji ozugbo wee kwụsị, ka ịzenarị mmebi nke eriri igwe nke mmiri na-abanye na mmanụ jụrụ oyi kpatara.

8. Akpaaka lubrication System

Ngwa mbanye mgbanaka na-eji ngwaọrụ mmanye mmanụ na-adịghị arụ ọrụ iji hụ na akụrụngwa nwere ike nweta mmanu ọnụọgụ akpaka na-akwụsịghị ọrụ ahụ wee kwalite ọnụego ọrụ.

9. Platform ọrụ ọgụgụ isi dị anya dabere na ịntanetị nke iheNkà na ụzụ

A na-etinye ihe ntanetị nke ihe na teknụzụ igwe ojii iji nakọta na nyochaa data arụmọrụ akụrụngwa n'otu oge iji ghọta ọrụ dịpụrụ adịpụ na mmezi, nchọpụta mmejọ na njikwa usoro ndụ zuru oke nke akụrụngwa.

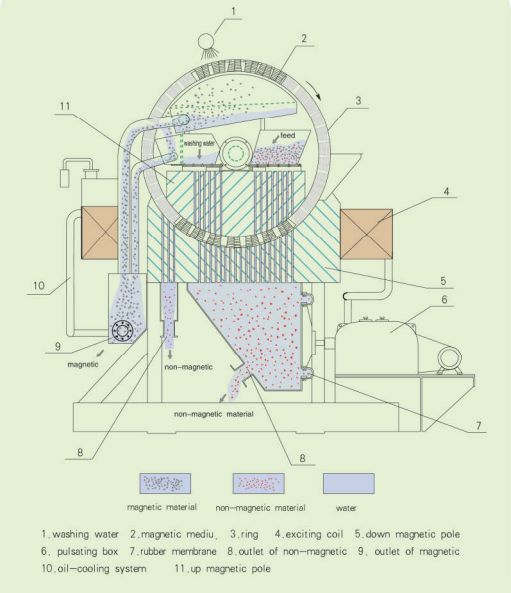

Ụkpụrụ ọrụ

A na-ewebata slurry na hopper nri site na ọkpọkọ nri, wee banye na magnetik magnetik na mgbanaka na-atụgharị n'akụkụ oghere ndị dị na ogwe ndọta dị elu. Ihe ndọta magnetik bụ magnetized, a na-emepụta oghere magnetik dị elu n'elu ya. A na-adọta ụmụ irighiri ihe ndọta n'elu matriks magnetik, a na-ebute ya na

ebe na-abụghị magnetik dị n'elu na ntụgharị nke mgbanaka ahụ, mgbe ahụ, a na-agbanye ya na nchịkọta nchịkọta site na nrụgide mmiri na-agbanye. Ihe ndị ahụ na-abụghị magnetik na-asọba n'ime ihe nchịkọta ihe na-abụghị ihe ndọta n'akụkụ oghere ndị dị na oghere magnetik nke ala ka a ga-ahapụ.

Ngwa

Ọ dabara maka mmiri ịta ahụhụ dị iche iche magnetik dara ọla dị ka hematite, limonite, specularite, manganese ore, ilmenite, chrome ore, obere ụwa ore, wdg, yana iwepụ ígwè na ịdị ọcha nke mineral ndị na-abụghị ọla dị ka. quartz, feldspar na kaolin.

Nkwalite

■Nkà na ụzụ jụrụ mmanụ-mmiri nke eriri igwe

■Sistemụ mkpofu mmiri ịnweta mmiri

■Sistemụ mkpuchi mkpuchi okpomọkụ

■Usoro mmanu mmanu akpaaka

■Matrix magnetik agbakwunyere ogologo ndụ

■Sistemụ njikwa akpaka ọkwa mmiri mmiri

■Sistemụ oti mkpu na-agbapụta oyi

■Sistemụ nleba anya nke ọma

Uru LHGC karịrị mgbanaka kwụ ọtọ whiMS

| Mgbanaka kwụ ọtọ whiMS nwere nchegbu | Ihe ngwọta LGGC |

| Igwe mmiri na-anabata waya oghere na usoro jụrụ oyi. Mgbidi dị n'ime waya dị mfe ịmepụta ọnụ ọgụgụ lime, ọ ga-abụrịrị na a na-ehicha acid mgbe nile, ọnụ ọgụgụ ọdịda dị elu, na ndụ eriri igwe dị mkpụmkpụ. | A na-emikpu eriri igwe ahụ n'ime mmanụ iji mee ka ọ dị jụụ, ma nakweere mgbasa ozi dị ukwuu na-asọpụta n'èzí, nke nwere nkwụsị ọkụ ngwa ngwa, mmụba dị ala ma na-enweghị mmezi. Ihe mkpuchi eriri igwe na-anabata usoro akpọchiri nke ọma, nke dabara adaba maka gburugburu ebe ndị ọzọ siri ike. |

| Matrix mkpanaka na-ada n'ụzọ dị mfe | Matriks ahụ na-eji otu akụkụ site na ụdị ihe owuwu, na mkpanaka ndị na-ajụ ase adịghị adapụ; na-edozi efere lug na-eji usoro nhazi conical, nke nwere ike njikọ dị elu ma ọ dịghị mfe imebi. |

| Ijubiga ókè | |

| Mmanya akwụkwọ ntuziaka, nchekwa dị ala | Mmanya mmanye akpaka gia na-adịghị arụ ọrụ, nchekwa na ntụkwasị obi |

| Iji aka na-arụ ọrụ na mmezi,na-arụ ọrụ ike | Njikwa ọgụgụ isi, ọrụ a na-atụghị anya ya |

The LHGC mmanụ-mmiri jụrụ vetikal mgbanaka high gradient magnetik separator (WHIMS)

(1.3T / 1.5T / 1.8T) Isi teknuzu paramita: (na-abụghị metal minerals)

Na ụkpụrụ, ihe nlereanya nhọrọ nke ngwá bụ isiokwu na ego nke ịnweta slurry. mgbe nkewa minerals iji.

ụdị ngwá ọrụ a, slurry ịta nwere ụfọdụ mmetụta na ịnweta nhazi index. Iji nweta mma ịnweta nhazi index,biko ibelata slurry ịta nke ọma. Ọ bụrụ na nha nke ihe ndọta dị na nri ịnweta ahụ dị ntakịrị elu, ikike nhazi ahụ ga-ejedebe na ngụkọta nke ịnweta mineral magnetik site na magnetik.

matrix, n'ọnọdụ ahụ, a ga-ebelata ntinye ntinye nri nke ọma.

| LGGC 1000F | LGGC 1250F | LGGC 1500F | LGGC 1750F | LGGC 2000F | LGGC 2250F | LGGC 2500F | LGGC 2750F | LGGC 3000F | LGGC 3500F | LGGC 4000F | LGGC 4500 | LGGC 5000F | ||

| Agbanyere ndabere (T) | 1.3 / 1.5 (1.8) Na-adị ugbu a na-agbanwe agbanwe | |||||||||||||

| Egosiri na-akpali akpali (kW) | 25 | 36 | 38 | 46 | 56 | 60 | 72 | 82 | 90 | 105 | 118 | 130 | 140 | |

| 35 | 42 | 53 | 58 | 68 | 78 | 85 | 100 | 120 | 130 | 140 | 156 | 172 | ||

| 56 | 68 | 82 | 98 | 115 | 130 | 150 | 165 | 180 | 205 | 230 | 248 | 268 | ||

| Ike (t/h) | 2 na 3.5 | 5 nke 9 | 10 ~ 15 | 15 ~ 25 | 25 ~ 40 | 33 ~ 60 | 40 ~ 75 | 50 ~ 100 | 75 ruo 125 | 125-200 | 175 ~ 275 | 225 ~ 350 | 300 ~ 480 | |

| Ike pulp (m3/h) | 12.5-20 | 20 ~ 50 | 50 ~ 100 | 75 ~ 150 | 100 ~ 200 | 160 ~ 300 | 200 ~ 400 | 250 ~ 500 | 350 ~ 650 | 550 ~ 1000 | 750 ~ 1400 | 1100 ~ 1700 | 1200 ~ 2400 | |

| Ugbu a na-atọ ụtọ (A) | 50 | 80 | 130 | 135 | 150 | 175 | 172 | 200 | 207 | 217 | 262 | 280 | 288 | |

| 80 | 125 | 140 | 150 | 180 | 215 | 216 | 250 | 285 | 268 | 285 | 300 | 340 | ||

| 150 | 160 | 280 | 290 | 310 | 320 | 330 | 340 | 348 | 350 | 362 | 372 | 385 | ||

| Njupụta nri (%) | 10 ~ 35 | |||||||||||||

| Nha nri (mm) | -1.2 | |||||||||||||

| Ọsọ ntụgharị mgbanaka (r/min) | 2 4 | |||||||||||||

| Mgbanaka elu dayameta φ (mm) | 1000 | 1250 | 1500 | 1750 | 2000 | 2250 | 2500 | 2750 | 3000 | 3500 | 4000 | 4500 | 5000 | |

| Ike moto nke mgbanaka (kW) | 1.1 | 1.5 | 3 | 4 | 5.5 | 7.5 | 11 | 15 | 18.5 | 30 | 37 | 45 | 55 | |

| Voltage na-akpali akpali (DCV) | (1.3T ~ 1.5T) 0 ~ 514 (Mgbanwe na nke ugbu a) / (1.8T) 0 ~ 695 Gbanwee na ugbu a) | |||||||||||||

| Nrụgide mmiri (Mpa) | 0.2 na 0.4 | |||||||||||||

| Oriri mmiri (m3/h) | 8 ruo 12 | 12-20 | 20 ~ 30 | 30 ~ 50 | 50 ~ 100 | 75 ruo 125 | 100 ~ 150 | 125-200 | 150 ~ 250 | 250 ~ 350 | 350 ~ 500 | 450 ~ 600 | 550 ~ 800 | |

| Arọ maka akụkụ (t) kacha ukwuu | 2.8/3 (4.7) | 3/6 (12) | 9/14 (20) | 14/19 (22) | 20/22 (28) | 22/23 (30) | 24/25 (32) | 25/26 (34) | 33/36 (38) | 50/52 (55) | 70/72 (75) | 74/77 (80) | 80/82 (85) | |

|

Akụkụ ndepụta (mm) | L | 2360 | 2500 | 2670 | 2880 | 3810 | 4570 | 3660 | 3915 | 4410 | 4740 | 5470 | 5980 | 6410 |

| 2510 | 2780 | 2700 | 3000 | 3250 | 4620 | 3850 | 4260 | 4570 | 5530 | 5750 | 6160 | 6680 | ||

| 3120 | 3210 | 3760 | 3970 | 4170 | 4750 | 5200 | 5380 | 5510 | 5680 | 5820 | 6270 | 6820 | ||

| W | 2700 | 2880 | 3320 | 3540 | 4320 | 4590 | 4690 | 4840 | 5540 | 5860 | 6350 | 6630 | 6840 | |

| 2850 | 3420 | 3700 | 3900 | 4080 | 4600 | 5050 | 5130 | 5820 | 5930 | 6750 | 6890 | 7170 | ||

| 2520 | 3580 | 3630 | 4330 | 5040 | 5230 | 5400 | 5620 | 5800 | 6350 | 6900 | 7210 | 7330 | ||

| H | 2450 | 2860 | 3400 | 3710 | 4250 | 4800 | 5290 | 5760 | 6450 | 7435 | 8570 | 9200 | 9700 | |

| 2630 | 3000 | 3650 | 4060 | 4480 | 4850 | 5500 | 5960 | 6610 | 7200 | 8650 | 9480 | 9650 | ||

| 2490 | 3300 | 3800 | 4300 | 4800 | 5280 | 5760 | 6250 | 6730 | 7950 | 9150 | 9600 | 9800 | ||

The LHGC mmanụ-mmiri jụrụ vetikal mgbanaka high gradient magnetik separator (WHIMS)

(1.1T / 0.6T) Isi teknuzu paramita: (na-abụghị metal minerals)

| LGGC 1000F | LGGC 1250F | LGGC 1500F | LGGC 1750F | LGGC 2000F | LGGC 2250F | LGGC 2500F | LGGC 2750F | LGGC 3000F | LGGC 3500F | LGGC 4000F | LGGC 4500F | LGGC 5000F | ||

| Agbanyere ndabere (T) | 1.1 / (0.6) Na-adị ugbu a na-agbanwe agbanwe | |||||||||||||

| Egosiri na-akpali akpali (kW) | ≤17/(10) | ≤19/(12) | ≤32/(15.5) | ≤37/(23) | ≤49/(29) | ≤51/(32) | ≤65/(41) | ≤69/(42) | ≤72/(50) | 93/ (52) | 102/(58) | 110/(65) | 128/(75) | |

| Ike (t/h) | 2-3.5 | 5–9 | 10-15 | 15–25 | 25–40 | 33–60 | 40 ~ 75 | 50 ~ 100 | 75 ~ 125 | 125-200 | 175-275 | 225-350 | 300~ 480 | |

| Ike pulp (m3/h) | 12.5–20 | 20 ~ 50 | 50 ~ 100 | 75-150 | 100-200 | 160 ~ 300 | 200-400 | 200-500 | 350 ~ 650 | 550 ~ 1000 | 750 ~ 1400 | 1100 ~ 1700 | 1200 ~ 2500 | |

| Ugbu a na-atọ ụtọ (A) | 41/ (70) | 70/ (85) | 110/(110) | 120/(125) | 140/(130) | 146/(120) | 165/(120) | 225/(100) | 185/(150) | 205/(180) | 263/ (205) | 270/(220) | 272/(330) | |

| Njupụta nri (%) | 10-35 | |||||||||||||

| Nha nri (mm) | -1.2 | |||||||||||||

| Ọsọ ntụgharị mgbanaka (r/min) | 2–4 | |||||||||||||

| Mgbanaka elu dayameta φ (mm) | 1000 | 1250 | 1500 | 1750 | 2000 | 2250 | 2500 | 2750 | 3000 | 3500 | 4000 | 4500 | 5000 | |

| Ike moto nke mgbanaka (kW) | 1.1 | 1.5 | 3 | 4 | 5.5 | 7.5 | 11 (7.5) | 15 | 18.5 (15) | 30 | 37 | 45 | 55 | |

| Voltaji na-akpali akpali (DCV) | 0~514 (gbanwee na nke ugbu a)) | |||||||||||||

| Mmiri nrụgide (Mpa) | 0.2 ~ 0.4 | |||||||||||||

| Oriri mmiri (m3/h) | 8-12 | 12-20 | 20-30 | 30 ~ 50 | 50 ~ 100 | 75 ~ 125 | 100-150 | 150-200 | 150-250 | 250-350 | 350-500 | 450-600 | 550~ 800 | |

| Ibu maka nnukwu Akụkụ (t) | 3.5/(2) | 4/ (3.5) | 9.3/ (4) | 15/(9) | 20/(13) | 24/(16) | 24/(17) | 21/ (18) | 33/(25) | 50/(47) | 68/(60) | 72/ (64) | 80/(72) | |

|

Nkọwapụta akụkụ (mm) |

L | 2360 | 2780 | 3000 | 2970 | 3170 | 4400 | 3660 | 3915 | 4410 | 4900 | 5470 | 6670 | 7100 |

| 2260 | 2680 | 2900 | 2870 | 3070 | 4300 | 3650 | 3910 | 4150 | 7400 | 5310 | 6220 | 7000 | ||

|

W | 2700 | 3270 | 3320 | 3540 | 3810 | 4400 | 4690 | 4830 | 5540 | 5500 | 6240 | 7150 | 7650 | |

| 2600 | 3110 | 3220 | 3440 | 3710 | 4300 | 3785 | 3910 | 4630 | 7750 | 5910 | 6740 | 7130 | ||

|

H | 2480 | 2850 | 3330 | 3710 | 4250 | 4600 | 5290 | 5760 | 6450 | 4400 | 8520 | 8930 | 9600 | |

| 2380 | 2750 | 3230 | 3610 | 4150 | 4150 | 5175 | 5650 | 6280 | 7200 | 8340 | 8850 | 9380 | ||

Okwu saịtị

WHMS nke mita ise kacha ukwuu n'ụwa

Nyefee emume

Iron Mine Project na Australia

Iron Mine Project na China

Quartz Sand Project na Austria